- New

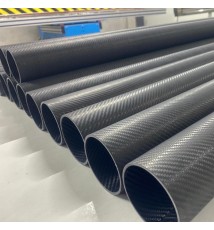

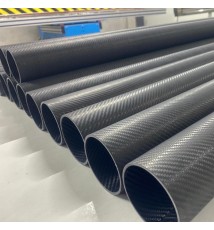

CARBONFİBER TUBES

Carbon fiber tubes are used in various industries due to their lightweight, durability, and high strength. In the aerospace industry, they are used in aircraft fuselages, wings, rotors, rockets, and spacecraft. Their lightweight improves fuel efficiency and performance. In the automotive industry, carbon fiber tubes are used in car chassis, sports car bodies, brake discs, and steering systems.

The combination of lightweight and high strength can enhance the performance of military equipment. Layers of carbon fiber tubes are produced in both 0° and 90° directions to achieve maximum strength, providing them with high strength in addition to the classic appearance of carbon fiber.

Carbon Fiber Tubes Technical Specifications and Applications:

Carbon fiber tubes are widely used in various industries due to their lightweight, durability, and high strength.

1- Aviation and Aerospace Industry: Used in aircraft fuselages, wings, rotors, rockets, and spacecraft. Their lightweight enhances fuel efficiency and performance.

2- Automotive Industry: Carbon fiber tubes are used in car chassis, sports car bodies, brake discs, and steering systems, aiding in weight reduction and performance enhancement.

3- Maritime Industry: Utilized in marine vessels, sailboats, mast poles, and underwater vehicles due to their resistance to seawater and lightweight nature.

4- Sports Equipment: Found in bicycle frames, golf clubs, fishing rods, tennis rackets, and kayak paddles, providing athletes with lightweight and durable equipment.

5- Construction Materials: Used in construction and building industries, particularly in applications like concrete reinforcement and strengthening.

6- Military Applications: Employed in military equipment such as armor plates, helicopter rotors, aircraft components, and weapon systems due to their lightweight and high durability, enhancing performance.

Carbon fiber tubes are manufactured using 100% carbon fiber epoxy prepreg. The layers are oriented at 0° and 90° angles for optimal strength. After curing, the tubes undergo calibration to ensure precise measurements. The TG value of our carbon fiber tubes is 120°C. Our 3k carbon fiber tubes can be used for demanding mechanical applications and offer a fantastic carbon fiber appearance. For a glossier look, the tubes can be coated with UV-resistant varnish, preventing them from yellowing due to sunlight exposure and resisting sea salt corrosion.

Production of Carbon Fiber Tubes:

Our carbon fiber tubes are manufactured using 100% carbon fiber epoxy prepreg. The prepreg layers are adjusted to ensure optimal orientation at 0° and 90° angles. After the curing process, the tubes undergo calibration to complete the measurement adjustments. The TG (glass transition) temperature of our carbon fiber tubes is 120°C.

Data sheet

Video