- New

- Out-of-Stock

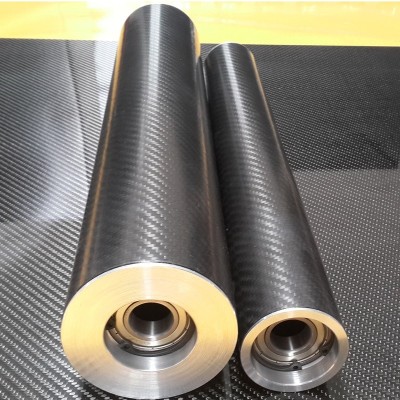

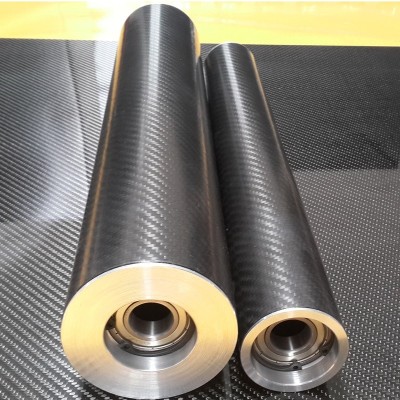

CARBON FIBER ROLLER

Carbon fiber rollers are manufactured by Kompozitsan according to the desired specifications and tolerances.

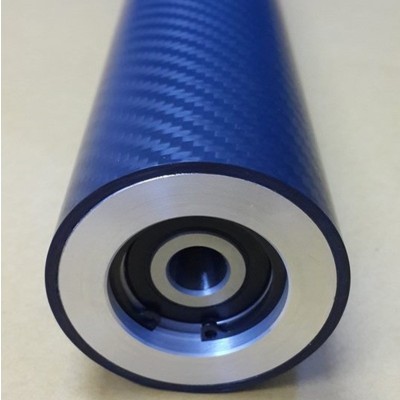

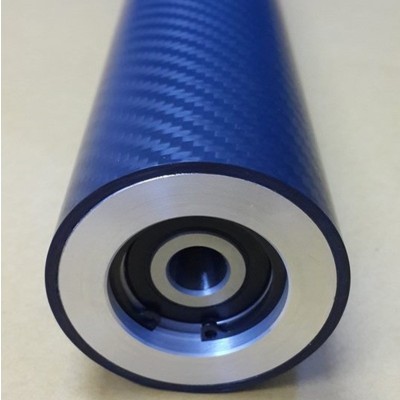

Features: Many machines produced with new technology use carbon fiber rollers. Carbon fiber rollers are particularly preferred in machines where static electricity is not desired and operate at high speeds. The rollers to be made are delivered to the customer as the final product with aluminum bearing housings glued to them, according to the required balance tolerances, diameter, and length.

CARBON FIBER ROLLER

Carbon fiber rollers are manufactured by Kompozitsan according to the desired specifications and tolerances.

Features: Many machines produced with new technology use carbon fiber rollers. Carbon fiber rollers are particularly preferred in machines where static electricity is not desired and operate at high speeds. The rollers to be made are delivered to the customer as the final product with aluminum bearing housings glued to them, according to the required balance tolerances, diameter, and length.

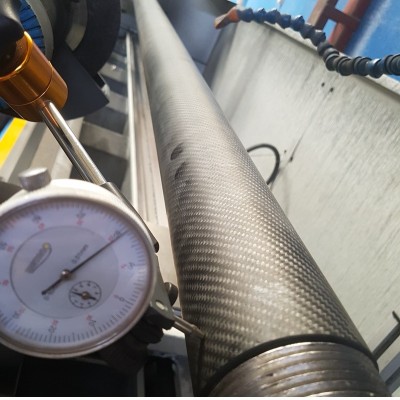

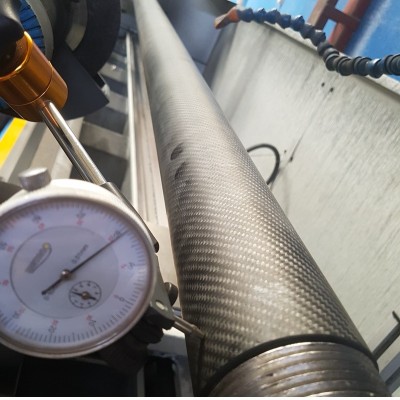

Balance and diameter tolerances may not be critically important for carbon fiber rollers. Carbon fiber rollers are produced with balancing and deflection control according to a tolerance of 2%. Before placing orders, it is necessary to fill out the attached Technical Drawing form completely. The aluminum bearings that will come to the front parts of the rollers are also manufactured by Kompozitsan, and after assembly, the deflection and balance final checks are performed again.

Kompozitsan produces a wide variety of carbon fiber rollers useful for idle rollers. Carbon fiber rollers provide an ideal solution to the inertia and bending/efficiency problems seen in metal cylinders. Carbon fiber rollers, weighing less than half of steel and less than 1/5 of aluminum, are the most suitable solution for demanding automation or conveyor applications.

Carbon fiber rollers are designed to reduce weight and increase speed. Lightweight, low-inertia idle rollers allow for faster production, reduce vibration, reduce waste, and improve product quality.

When carbon fiber rollers replace traditional steel or aluminum cylinders, production capacity increases significantly. When carbon fiber rollers are installed, machines can operate faster.

These improvements in shaft and cylinder performance directly affect efficiency and increase machine efficiency.

Carbon fiber rollers are absolutely necessary for this field.

Video